Container Washing Systems

Our line of container washing systems are designed for a variety of applications and can be used to clean grease, oil, automotive lubricant, paint, coating, ink and more. Systems can be designed to use aqueous, caustic or solvent cleaning chemistries – we can help you determine what will be most effective for removing your contaminants.

Why Container Washing Systems?

Get consistent, fast, reliable container washing results. Plus, re-deploy labor to safer, more productive tasks.

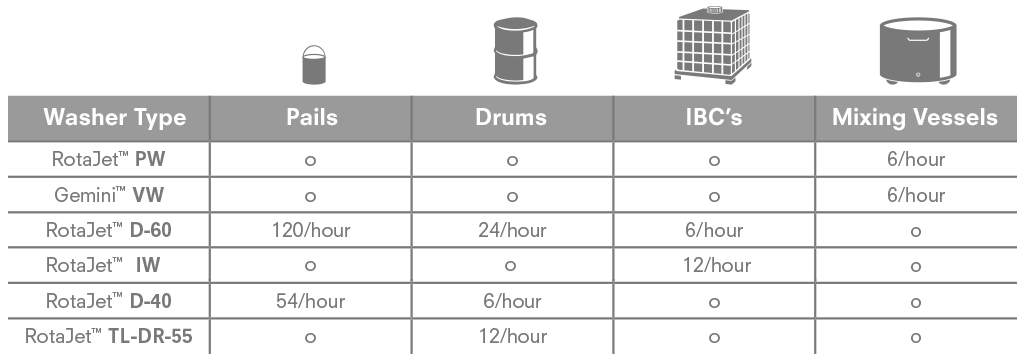

With simple operation, consistent clean results, and predictable wash times (typically 10 minutes per batch or less), production schedules can rely on available clean containers like clockwork. Check the estimated quantities per hour below by system and container type.

Employees who perform manual cleaning operations are subject to ongoing exposure to cleaning agents such as caustics, detergents or solvents. Create a safer environment with automatic, vented systems, and avoid costly workplace injury hazards.

Various Chemistries Available

Container washers can be tailored to clean grease, oil, automotive lubricant, paint, coatings, inks and more.

Our line of container washing systems are designed for a variety of applications, and can be used to clean grease, oil, automotive lubricant, paint, coating, ink and more. Systems can be designed to use aqueous, caustic or solvent cleaning chemistries. Our container wash systems can clean your containers with the chemistries which are most effective for removing your contaminants.

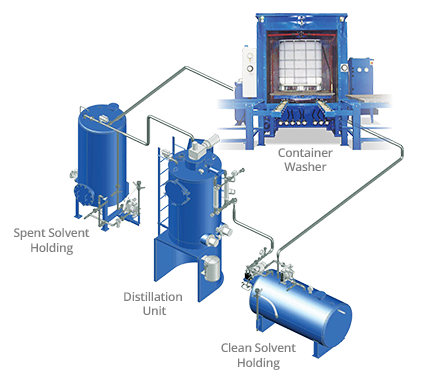

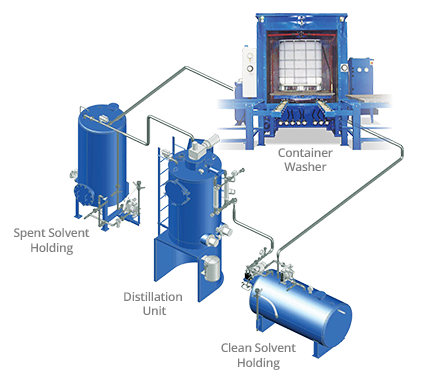

Closed-Loop Container Washing

Completely integrates with PRI solvent recycling systems.

Container Cleaning Systems can be designed to fit perfectly within your operation, with integrations into your water treatment system, production assembly line, paint filling line, or solvent recovery system.

Our container washing systems are often incorporated into complete turn-key solvent recovery and recycling systems, using a closed-loop process. In this process, spent solvent is collected and fed into a distillation unit, where the contaminants can be separated from the reusable solvent. Contaminants are discarded and reusable solvent is automatically fed back through the cleaning process.