RotaJet™ PWHigh Pressure Spray Vessel Washer

The RotaJet model PW is a high-pressure spray washer, designed to quickly and efficiently clean both the interior and exterior of mixing vessels.

Enclosed, High Pressure Spray

Interior & Exterior Cleaning

The RotaJet by PRI (Model PW) is designed for cleaning mixing vessels ranging from 61” (1550mm) tall with diameters from 24” (600mm) to 69” (1750mm) and volumes from 100 gallons (378L) to 850 gallons (3218L). The dirty vessels are places onto the lifting lid. Once locked into position, the vessel is loaded into the wash chamber using a hydraulic jack system. The cleaning process is fully automated, and the vessels are washed, rinsed and dried, ready for production. Fumes are vented prior to opening the system, to limit employee exposure.

- high pressure spray

- interior and exterior cleaning

- wash, rinse and dry cycles

- fume venting system

- explosion-proof pneumatic controls

Enclosed, Pressurized Wash

Fully enclosed during wash cycle, allowing for high pressure.

The system typically uses heated alkaline detergent to wash vessels. Once vessels are placed on the platform and locked in place, the vessel is raised into the wash chamber and sealed for the cleaning cycle to start. After caustic washing, the vessels are rinsed with water and flashed dried, ready to be used in production for a new batch of ink or paint.

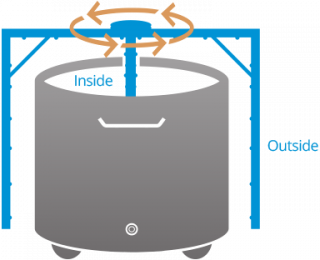

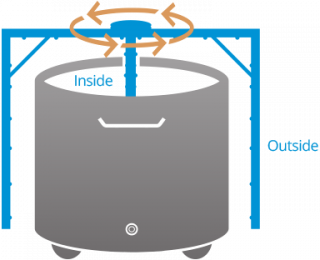

Interior & Exterior Cleaning

High pressure spray nozzles clean both the inside and the outside of the vessel.

The RotaJet PW includes a spray insert that is placed inside the open vessel, with articulating arm sprayers that surround the vessel. Once placed inside the wash chamber, the door is sealed, and the spray nozzles spin, delivering pressurized cleaning agent to both the interior and exterior of the vessel.