LSR™Large Scraped Solvent Recycling

The largest of the solvent reclamation line, the LSR™ Series is built to handle high solids, large-scale waste streams. An ASME Code stainless steel vessel houses the patented rotating scrapers that continually scrapes the sidewalls and mixes the solids. LSR™ also features a steeper cone-shaped vessel, which enables better heat transfer, and more efficient solvent reclamation.

LSR™

Large-Scale, High Solids Solvent Recycling System

The LSR™ Solvent Distillation system is the largest single-stage solvent distillation system in the industry. The LSR™ allows you to recover large quantities of waste solvent containing high solids content, reducing waste and cost.

Maximize Solvent Recovery:

- cut virgin solvent purchase volumes

- reclamation rates as much as 90%

- reduce hazardous waste disposal volume

- units typically pay for themselves in a few months

Reduced Environmental Impact & Increased Safety:

- reduce the risks associated with large volumes of hazardous waste

- reduce your facility’s environmental footprint

Durable, Reliable, and Protected

PRI 10 Year Standard Limited Warranty

PRI solvent recovery systems carry the lowest life-cycle cost in the industry; over 75% of units sold in the last 15 years are still in service.

With proper care and maintenance, a PRI solvent recycling system can last for decades. That’s why we’re not afraid to back it up with a 10-year limited warranty on the distillation vessel. With PRI, you can trust that your solvent distillation system will be running for years to come.

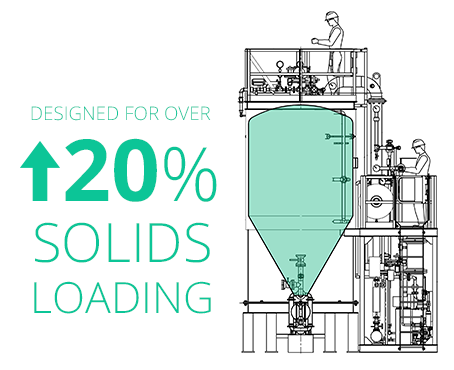

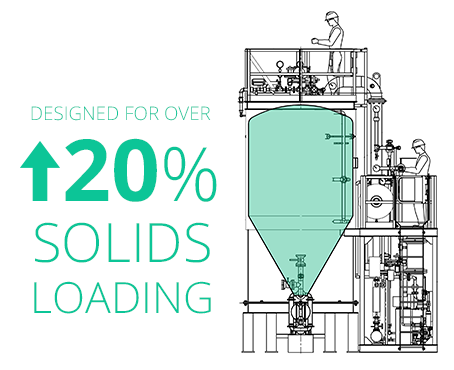

Designed for More Solids!

Steeper Cone-Shaped Vessel Distributes Solids Efficiently

The inside of the LSR™ solvent recycler features a steep cone-shaped vessel, which enables the most efficient reclamation of solvent from heavily solids-laden waste streams; this allows for a more efficient transfer of heat. The conical shape places the heat transfer source closer, and covers a larger contact area of the solvent mass.

As waste solvent is fed at the top of the cone, a steam jacket heats the cone, and the waste. The cone shape allows for a better transfer of heat throughout the vessel, and more solvent recovery from the waste stream.

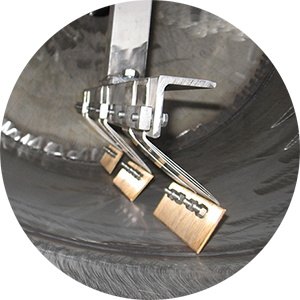

Long-Term, Consistent Output

Scraper Blade Assembly

The LSR solvent recovery system is designed for maximum efficiency. Our patented scraper blade assembly:

- cleans the heat transfer surface of sludge buildup for high efficiency

- all the heat transfer area below the liquid operation level is cleaned

- solids are rolled off the side walls and down into the conical bottom, speeding up the solvent distillation process

- gently agitates and mixes the contents of the distillation vessel

Available Models:

| LSR-80 | 1544 L (408 G) |

422 L/h (111 G/h) |

3629 kg (8000 lbs) |

| LSR-120 | 2419 L (639 G) |

568 L/h (150 G/h) |

4536 kg (10000 lbs) |

| LSR-160 | 5288 L (1397 G) |

1007 L/h (266 G/h) |

5443 kg (12000 lbs) |

| LSR-200 | 9024 L (2384 G) |

1514 L/h (400 G/h) |

6804 kg (15000 lbs) |

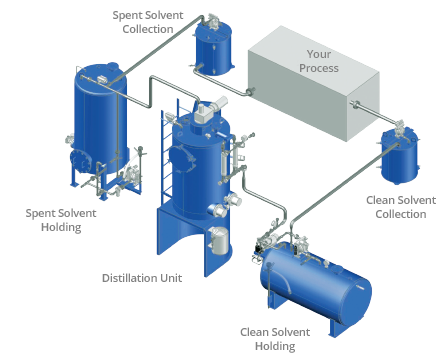

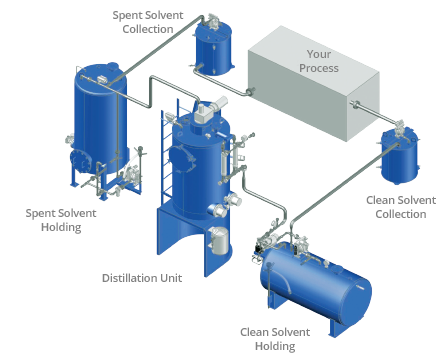

Closed-Loop Solvent Recycling

Spent solvent collection, distillation, and clean solvent holding. Directly integrated into your process.

Our solvent recovery systems are often incorporated into a complete closed-loop solvent management system, utilizing PRI’s specialized and custom-designed Clean and Dirty Solvent Tanks with feeds.

In a closed-loop process, waste solvent is collected in a Dirty Solvent Tank, then piped to a Distillation System to separate the contaminants. Then, contaminants are discarded and reusable solvent is automatically sent to a Clean Solvent Tank, which feeds your production process. PRI can engineer solvent management systems to support parts washing, paint lines or other manufacturing processes where solvents are used.