Solvent Recycling

PRI’s proven and effective solvent recycling systems provide clients with a clean, green and reliable solution to recycle contaminated solvents. With one of the largest family of solvent recycling systems, PRI systems are rugged and durable, often with 20+ year operational life, and are among the safest and affordable solvent recovery systems available in the world.

Engineered for Life.™

The longest lasting, highest efficiency family of solvent recycling systems, from the company who pioneered solvent recovery in 1983.

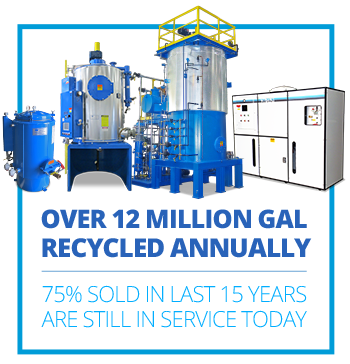

When it’s time to buy a Solvent Management System, spend wisely. With one of the largest installed base of solvent recycling systems, our clients actively recycle over 12 million gallons of solvent per year, and growing. Plus, PRI systems carry the lowest life-cycle cost in the industry, with high durability and long life – over 75% of our systems sold in the last 15 years are still in service. Only PRI offers a 10 year warranty on the distillation vessel, offering the best value and durability in the industry.

Why Solvent Recovery?

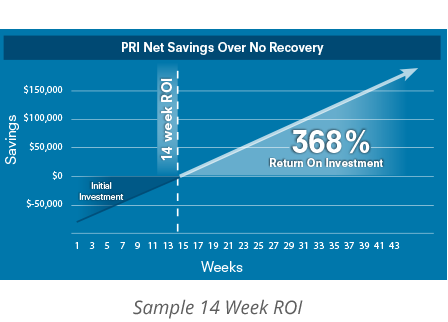

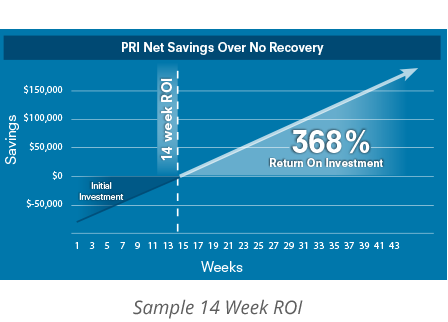

It Pays for Itself.

On-site solvent recovery and solvent recycling is the most affordable long-term option for companies who generate solvent waste. Our equipment can in many cases enable recovery of more than 90% of waste solvent, reducing disposal and new solvent expenses, and delivering a return on investment in a matter of months.

- assurance of regulatory compliance

- ability to reuse spent solvent

- lowered removal and disposal costs

- reduced inventory and new solvent purchase costs

- increased quality control over purchased reclaimed solvent

- reduced liability associated with waste solvent

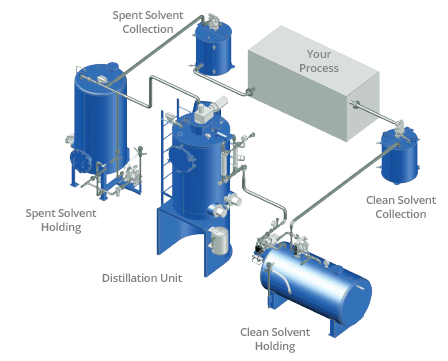

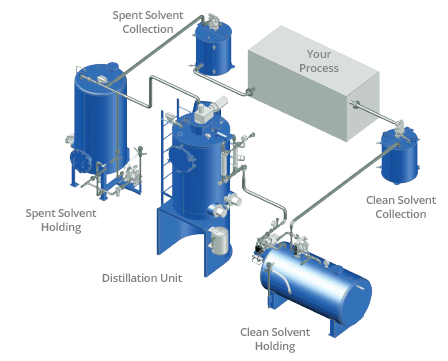

Closed-Loop Solvent Recycling

Spent solvent collection, distillation, and clean solvent holding. Directly integrated into your process.

Our solvent recovery systems are often incorporated into a complete closed-loop solvent management system, utilizing PRI’s specialized and custom-designed Clean and Dirty Solvent Tanks with feeds.

In a closed-loop process, waste solvent is collected in a Dirty Solvent Tank, then piped to a Distillation System to separate the contaminants. Then, contaminants are discarded and reusable solvent is automatically sent to a Clean Solvent Tank, which feeds your production process. PRI can engineer solvent management systems to support parts washing, paint lines or other manufacturing processes where solvents are used.