ThermoDecoN™

The ThermoDecoN™ offers a simple, low pressure batch effluent decontamination system in one small footprint. The system is designed for small mobile labs, hospitals or research facilities, with low resources and tightly-controlled effluent profiles.

Batch, Low Temp Option

Low resource, low cost decontamination.

The ThermoDecoN™ provides an economical solution for effluent decontamination, at facilities where costs and utility resources are a chief concern. For simplicity of maintenance and reduction of ongoing costs, ThermoDecoN™ components are available worldwide.

- Fully automated sequential batch processing

- High level disinfection- 10-6 B Atrophaeus/Subtilis

- Operating capacity: 378L (100 G) to 3,028L (400 G)

- No PLC

- Adjustable electronic temperature control up to 96˚C (205 ˚F)

- Adjustable electronic timer to ensure effective “hold time”

- NEMA 4 control cabinet

- Simple utilities: (220V / Single Phase)

- No air, no steam, no water needed (water recommended)

- Chemical injection port for CIP

- Gravity discharge to sewer at < 60˚C (140 ˚F)

Economical, Basic Process

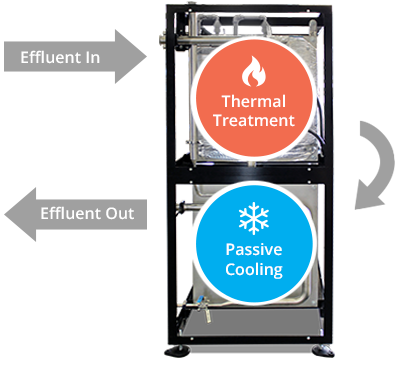

Low pressure, passive cooling.

The ThermoDecoN™ offers a simple, easy-to-understand operation. The batch operation provides flexibility for different types of waste streams, and treats effluent in an automatic operation as the un-treated effluent is produced.

- Un-treated effluent enters the system from your process

- The effluent is heated in the Treatment Tank (<100°C)

- Effluent is held at temperature for the time selected by the user

- Once treatment is completed, effluent is transferred into cooling tank

- Cooled effluent is discharged by gravity

Biological Validation By Design

The ThermoDecoN™ includes design features to allow routine validation of the system. We understand the importance of a properly functioning biowaste treatment system, and that our users require routine validation. It is for these reasons that all of our biowaste treatment systems have built-in validation design features to allow staff to ensure the process is effective and leads to consistent results, without making the process cumbersome or inconvenient for you.

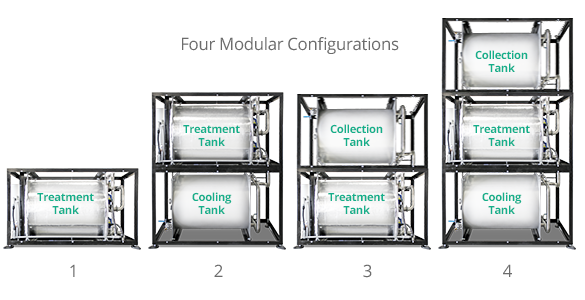

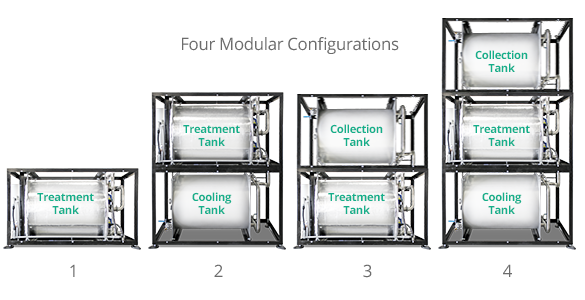

Configurations & Options

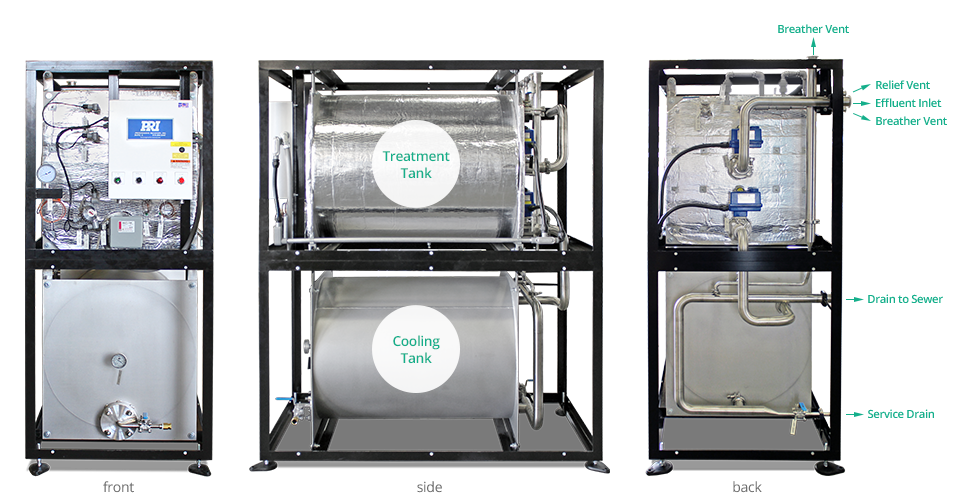

The simplistic design of the ThermoDecoN™ makes modular configurations easy. Tanks include Treatment, Collection, and Cooling. At it’s smallest configuration, the Treatment Tank doubles as a Cooling Tank. Additional collection and cooling tanks can be added to accommodate larger volumes and faster processing, cooling of batches.

Other options include:

- digital process logger with USB port

- cooling water injection port

- discharge/lift pump

- sterile vent filters