ThermoBatch™

Treats biologically active wastewater in research facilities from BSL-2 through BSL-4 biocontainment levels. In high containment and other facilities where safety is paramount, where solids are present, where redundancy is required, and where flexibility is necessary, ThermoBatch™ is the #1 choice across the globe.

#1 Choice in Batch Effluent Decontamination

Engineered for life.™ Proven, reliable, durable.

ThermoBatch™ is a leading effluent decontamination system for Veterinary Research and Diagnostic Labs; Human Diagnostic and Research Facilities; and other high containment facilities producing biowaste effluent.

- world class experience – over 35 years, 3,000 systems in 36 countries

- maximum flexibility – any capacity, flow profile, or treatment process

- highly configurable design – scalable, redundant, feature-rich options

- fully automated – unmanned operation, minimal maintenance

- trusted – largest installed base worldwide, including containment

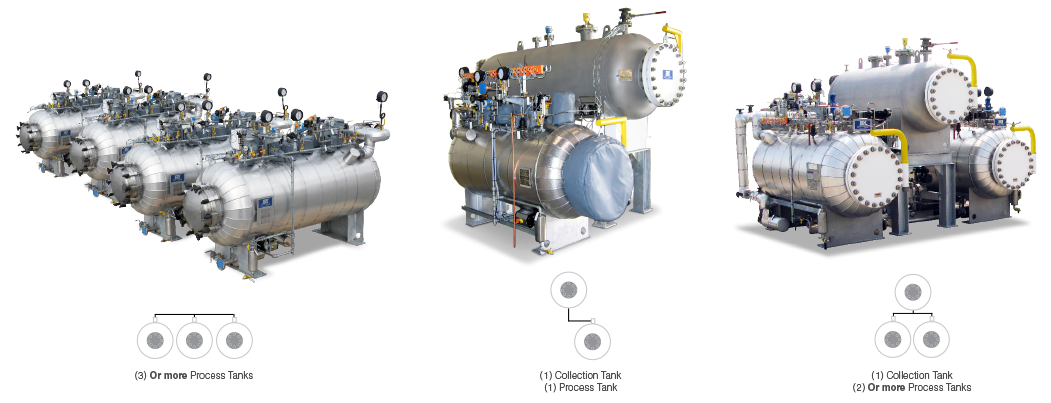

Maximum Flexibility

Any capacity, flow profile, or treatment process.

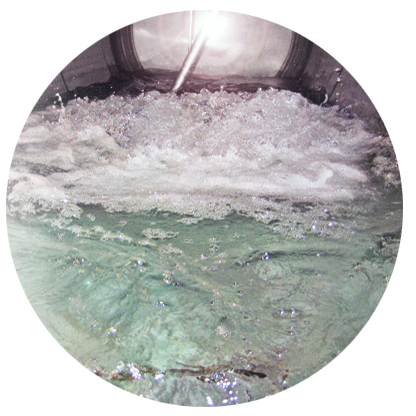

The ThermoBatch™ effluent decontamination system is capable of handling both liquids and liquid/solid mixtures, making it one of the most versatile treatment systems on the market. ThermoBatch™ easily adapts to the requirements of your waste stream and program changes.

- any capacity – up to more than 350,000 gal/day

- sterilization greater than 6Log10 reduction

- treatment of liquids and liquid/solid mix

- batch process offers high level of assurance

- BSL-2 through BSL-4 containment facilities

- widely accepted and easy validation protocols

- fully automated

- effluent cooled prior to discharge

- sterile filter modules available

- internally agitated for efficiency

Biological Validation By Design

The ThermoBatch™ includes design features to allow routine validation of the system. We understand the importance of a properly functioning biowaste treatment system, and that our users require routine validation. It is for these reasons that all of our biowaste treatment systems have built-in validation design features to allow staff to ensure the process is effective and leads to consistent results, without making the process cumbersome or inconvenient for you.

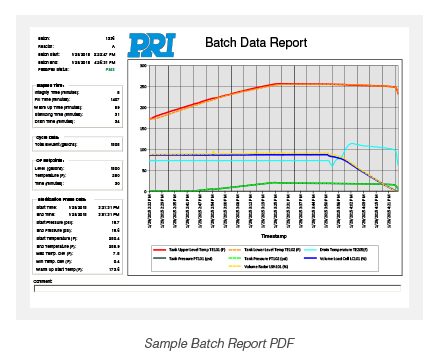

Data Logging

Process Assurance Batch Reporting Software

PRI’s batch report software continuously monitors the effluent decontamination system and generates a “proof of process”, assuring employees, officials, and the public of a safe environment. The software collects the performance data for each batch and generates a report representing the Time, Temperature, and Pressure of the operation, proving the system performed to the set points during the testing phase.

This validates that complete and proper treatment has been achieved. Other features and benefits include:

- proof of process for public assurance

- documented evidence for each batch

- excellent troubleshooting tool

- pass/fail result for each batch

- HMI display, printout and PDF, historical data archive

Green, Chemical-Free Technology

Heat + Time = Sterilization

The ThermoBatch™ effluent decontamination system relies on a combination of time and temperature to treat the waste stream. This makes the ThermoBatch a very environmentally conscious option. Units are wrapped in an insulated steam-heated dimple jacket conducting uniform, consistent heat.

This, combined with other options such as energy recovery systems, allow ThermoBatch™ to maintain reduced utility and operational costs.