Effluent Treatment Levels

Understanding the efficacy of any effluent decontamination system is the first step in selecting the proper treatment process. Different types of systems can achieve different levels of treatment which include sterilization & decontamination levels and the user must evaluate the requirements and select the proper treatment level.

The typically used term “decontamination” is generally used as a description of labeling something “safe.” This has different meanings depending upon how it is being applied and is not descriptive of the process necessary to achieve a specific result or describe a piece of equipment to meet that result. Several entities, including the Centers for Disease Control and Prevention and State and Territorial Association on Alternate Treatment Technologies, have outlined levels of disinfection and treatment with prescribed requirements for achieving a particular level. These guidelines with the addition of a proper Risk Assessment will direct the user to a required level of treatment for a specific application or facility.

- Level I – (Low Level Disinfection) Inactivation of most vegetative bacteria, fungi, and lipophilic virus.

- Level II – (Intermediate Level Disinfection) Inactivation of all vegetative bacteria, fungi, all viruses, and mycobacteria.

- Level III – (High Level Disinfection) Inactivation of all vegetative bacteria, fungi, all viruses, mycobacteria, and B. stearothermophilus spores at 4Log10 or greater; or B. subtilis spores at 4Log10 or greater with chemical treatment.

- Level IV – (Sterilization) Inactivation of all vegetative bacteria, fungi, all viruses, mycobacteria, and B. stearothermophilus spores at 6Log10 or greater.

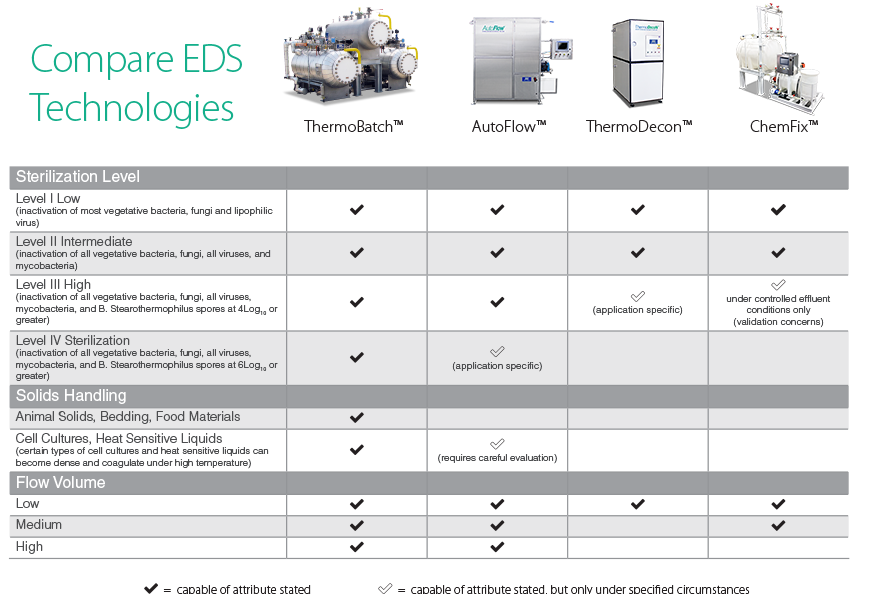

PRI Bio‘s ThermoBatch™ and AutoFlow™ can achieve Level IV (sterilization). Many US states as well as other countries (Canada, UK, Japan and others) have adopted a minimum of Level III treatment for any potentially pathogenic “medical waste.” While lower levels of treatment may provide a desired level in a given application, utilizing these protocols may not be in agreement with governing regulatory agencies.

Compare Effluent

|

ThermoBatch™ ThermoBatch™ |

AutoFlow™ AutoFlow™ |

ThermoDecoN™ ThermoDecoN™ |

ChemFix™ ChemFix™ |

| Sterilization Level | ||||

| Level I Low | ||||

| Level II Intermediate | ||||

| Level III High | effluent conditions only) |

|||

| Level IV Sterilization | ||||

| Solids Handling | ||||

| Animal Solids, Bedding, Food | ||||

| Cell Cultures, Heat Sensitive Liquids | ||||

| Flow Volume | ||||

| Low | ||||

| Medium | ||||

| High |

Categories & Tags

ISO 9001:2015