Mechanical Requirements for Effluent Decontamination Systems

Your Effluent Decontamination System (EDS) needs to function effectively and efficiently for your facility. Achieving this requires a collaboration between the experts about your building and the experts about our systems – and PRI Bio has a dedicated team of engineers that do this on a daily basis. Capacity, flow profile, space allocation, redundancy, ingress, and utilities are all factors that need to be taken into account to design the ideal system for each application.

Capacity, Flow Profile & Space:

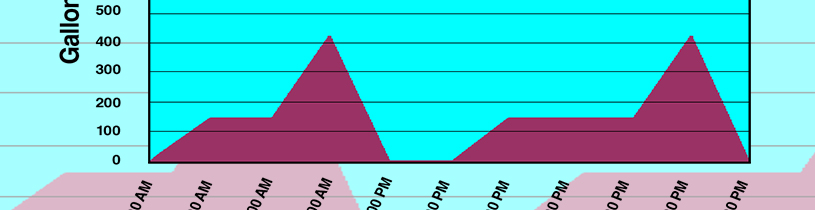

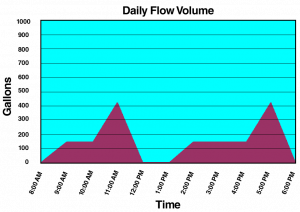

A good starting point in any design is going to be size and two simple things need to agree the system size versus the room size. Once the physical space is worked out, the system capacity can be left to an easy combination of a steady volume over a known timeframe, if the effluent waste is consistent. If not consistent, it may need to be mapped out in a flow profile. For example, it may include personnel showering in and out of a lab several times a day, all of the bathrooms and sinks, and may be further complicated if animal holding and necropsy waste are included.

Redundancy:

For most facilities, their production schedule and/or their biosafety needs present a situation in which the EDS has little or no room for error. This is why we go through such a detailed assessment and design process up front. In some cases the need is so serious that EDS redundancy will be needed. For example, a facility may decide they need the capacity to hold a full day of effluent in the case of failure, or they may want to have an entire second system on stand-by. These considerations can be made during the design phase for security and preparedness.

Ingress:

Ingress:

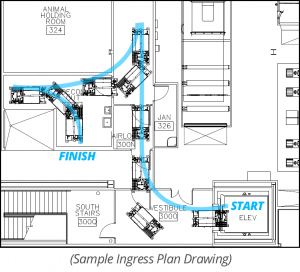

Once the system size, configuration, and space are determined the focus is moved onto getting the system into the building. An effluent decontamination system is not always an oversized series of high capacity tanks – some EDS’ can be a single skid, self-contained cabinet. But depending upon the system type, and facility circumstances ingress can be a challenge. Is the facility still being built? If not, are the doors and hallways large enough to accommodate the largest components of the EDS? During the design phase of the project, if ingress is going to be a challenge, our engineering team will work with you to develop a detailed ingress plan. In some cases, parts of the EDS may need to be disassembled and re-assembled onsite, while in other cases, ingress is as simple as knowing which hallways and doorways offer the largest openings.

Utilities:

An EDS can be designed to utilize different types of resources to treat waste such as steam or oil jacket, electric immersion heat, heat exchangers, or chemical treatment. Steam is commonly used as the source of heat to reach inactivation temperatures. What if your facility doesn’t have steam available or only has a limited supply and/or pressure? Aside from sizing and quoting a stand-alone steam generator to accompany the system, the equipment can be customized for other utility usage. Electricity and gas can also be used in combination with a heat transfer fluid exchange system to heat the unit. Plant air, instrument air, different voltage ratings, chemical supplies, chilled water, and other utilities might be needed for the system and would be addressed as necessary. A solid understanding of the utilities available at your facility will be critical to a successful EDS installation.

Energy Recovery:

During the development of an EDS, there are considerations that can be made to reduce the energy required, and save money in the long run. For example, a series of heat exchangers may be used to transfer already-heated effluent across incoming cold effluent to reduce the energy required to treat the incoming waste. Other energy conservation methods can be made, such as insulated steam piping, instrumentation, and tanks to reduce the heat loss. Our team can evaluate other options for you during the design process.

The design of a proper biowaste decontamination unit is complex and requires open lines of communication between supplier and end user. At PRI Bio we find it beneficial to start consultation conversations early to determine the needs of your facility and deliver the best system for your application. Contact an expert today to start discussing your project.

Categories & Tags

ISO 9001:2015