Regulated Waste Treatment Ecodas by PRI™ Shred & Steam Sterilizers

Ecodas by PRI™ offers a wide range of treatment systems for solid regulated infectious waste. Systems designed for hospital sharps and red bag waste, single-use biopharmaceutical manufacturing, to high-containment waste such as animal bedding.

Take Control of Your Waste

Reduce Costs, Liability & Impact

Ecodas by PRI™ systems are a versatile option for the on-site treatment of difficult solid waste streams, such as regulated medical waste, single-use disposables, roller bottles, bedding and others. The system offers a shred and steam sterilization process (treatment greater than 6 log reduction) that reduces overall waste volume density by up to 80%.

On-site treatment greatly reduces reliance upon external contractors who often use treatment methods such as incineration, which are harmful for the environment and energy-inefficient. Ecodas by PRI™ can reduce material transport, treatment and disposal costs by up to 30% to 50% over hazardous haul-away treatment services. Avoidance of incineration lowers energy use and carbon emissions.

Once treated, the waste material is rendered as common municipal waste, appropriate for standard disposal, or recycling where applicable.

Highly Effective Shred & Steam Sterilization Process

Shred Ensures Efficacy of Steam Treatment

The patented Ecodas process shreds all material once the vessel lid is closed, prior to the start of the steam treatment cycle, to ensure the efficacy of the steam sterilization throughout the load. The system uses direct heated steam and pressure to completely sterilize infectious waste, surpassing traditional autoclaving by rendering the waste unrecognizable due to the integrated shredder system. Temperature, pressure and time are continuously monitored and maintained through the integrated control system. Achieves microbial inactivation greater than 106.

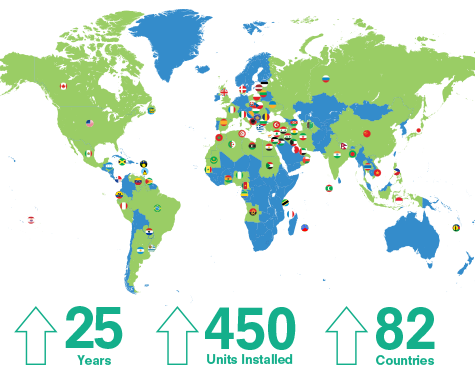

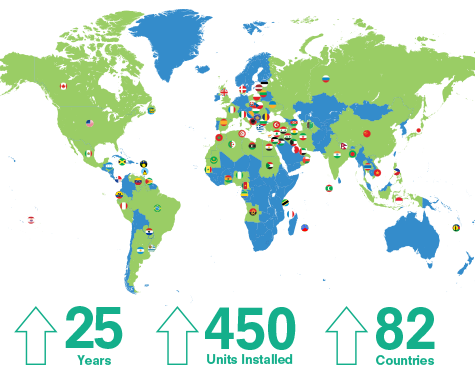

Proven, Worldwide Presence

Over 450 Units in More than 82 Countries

For over 25 years, Ecodas has been supplying companies with advanced medical waste treatment systems and environmentally-friendly solutions. With more than 450 units installed in over 82 countries around the world, customers trust Ecodas to provide high quality treatment and disposal systems that are safe, reliable, compliant, and cost-effective, protecting the public health while preserving the planet.

Ecodas is an ISO 9001 certified quality manufacturer, with a commitment to continuous improvement, adapting manufacturing standards to meet local codes, including ASME. Ecodas systems have been approved in 44 US states, and have been evaluated to meet high level microbial inactivation – Level IV according to STAATT I and STAATT II standards.

How It Works

The Ecodas by PRI™ family of systems are a hybrid autoclave that processes hazardous solid wastes in as fast as only 30 minutes, achieving high level sterilization, destruction, cooling and drain.

- Loading of waste through the top opening.

- Shredding starts as soon as the lid is closed, sealed and locked. Heavy-duty shredder automatically detects and prevents jams.

- Heating using steam, raising temperature to 300°F at 51 psi.

- Sterilization achieved maintaining pressure and heat for 10 minutes (adjustable time/temp for material density). Achieves microbial inactivation of 106 – 108 reduction.

- Cooling through the flash tank lowers temperature and pressure to prepare for system opening.

- Draining of condensate and cooling water into sanitary drain.

- Unloading of the sterilized waste discharged into totes, while liquid may go to an Effluent Decontamination System (EDS).