Integrated N2 Purge Filling System Allows Clean Filling of Isocyanates

Missed Han Nijland, Managing Director of Gemini Techniek’s presentation on an innovative new filling system to cleanly fill Isocyanates at the American Coatings Show? Don’t worry- we have you covered.

What Are Isocyanates and Why are They Challenging?

Dealing with Isocyanates in a filling system can be a very challenging task. Isocyanates are a transparent compound with a medium viscosity, made of primarily Nitrogen and Carbon, and are used in paints where polyester and acrylics are used as binders. Isocyanates dry quickly when exposed to open air, reacting with the Oxygen and Hydrogen. Once cured, the result is an improved shine/gloss and surface durability. It is because of these advantages that trains, airplanes and other high resistance applications use Isocyanate paints for surface protection. However, this can cause problems during a filling process.

Traditional Filling Systems are Not Suited for the Task

For a filling system handling Isocyanate paints, the primary problem is that curing takes place during storage and/or filling, and can clog the filling chamber. As a result, extensive cleaning is required on an ongoing basis, and the paint product will be prone to curing in the can.

Traditional filling systems are not suited for dealing with Isocyanates because of the way the filling chamber is designed. In any semi-automatic filling system, the filling cylinder/chamber contains a piston that moves up and down, bringing product into the chamber, then depressing to dispense the product into the container. In a traditional filling system, the top of this cylinder is open, allowing Oxygen and moisture to flow into the chamber. With most paints and coatings this would not be an issue, but with Isocyanates, this initiates the curing process prematurely, and quickly.

The Nitrogen Purge Filling Solution

To combat these issues, Gemini Techniek developed a system which adds a N2 (Nitrogen) Purge to the empty product can/container, the whetted filling chamber parts, as well as each of the filling valves. The primary goal being to purge as much Oxygen and Hydrogen from both the container and the filling chamber. Here’s how the Nitrogen-purged filling system works:

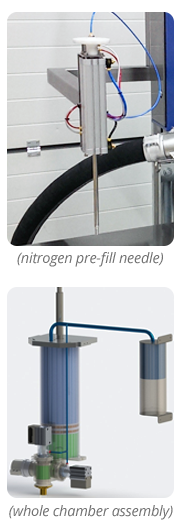

- Prior to moving to the filling station, the open container pauses at a Nitrogen injection needle, which fills the container with Nitrogen, purging the air.

- The top of the cylinder/filling chamber is sealed with a Teflon (PTFE) plastic cap, with a sealed penetration for the piston and Nitrogen tube, with individual Nitrogen tubes running to each filling valve.

- Chemically-dried Nitrogen is added to the cylinder/filling chamber while the piston dispenses the product, and to each of the filling valves mounted under the filling cylinder.

- Once the can/container is filled, it can move to the closure mechanism and off of the line.

Prevention of the curing process allows you to cleanly fill Isocyanates consistently and easily, without requiring the continuous cleaning of the filling system during the process.

Even with the Nitrogen-purge advancements, since Isocyanates are not being used very often in the filling process, the system should still be cleaned at the end of the day. Once a day’s batch of containers is filled, the system can be easily taken apart, cleaned, and set aside for the next day, or for the next batch. These advancements make the system easy to understand, easy to operate, and suitable for the complicated handling of Isocyanates.

Categories & Tags

ISO 9001:2015