Thermal Tissue Digester™ The Smartest Choice in Carcass Treatment

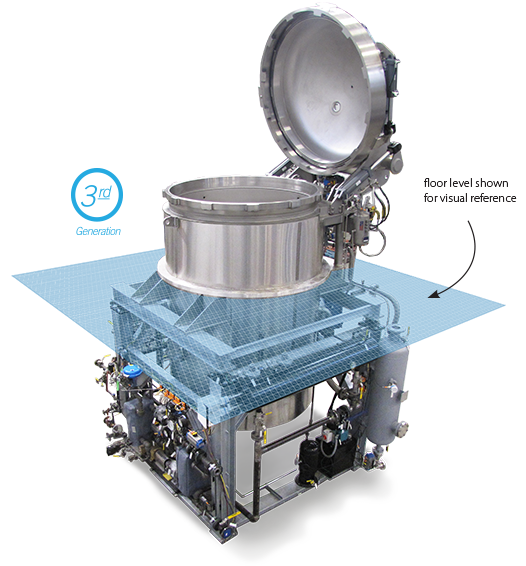

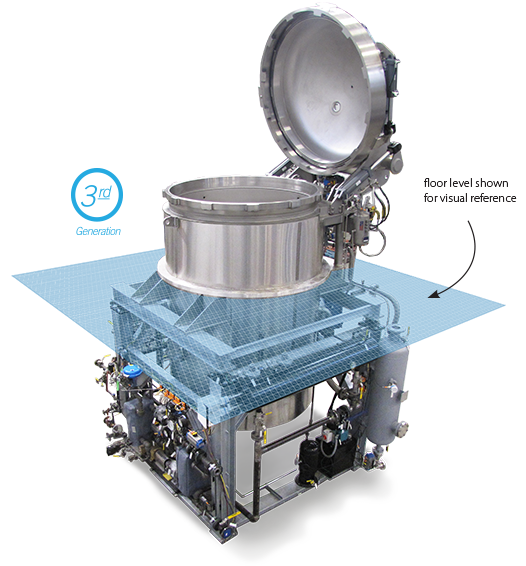

The most advanced – the only – third generation digester system, offering prion inactivation, flexible discharge options, high containment features, lowest operating costs, and low environmental impact.

Proven, Onsite Carcass Treatment

Lowest Cost of Ownership Over Other Systems

PRI Bio’s patented Thermal Tissue Digester (TTD) represents a revolutionary advancement in tissue disposal and sterilization, by using agitation and heat to break down tissue (with or without alkali), minimizing water and caustic use in the process.

The TTD offers the lowest operating cost for carcass disposal over alternative systems or incineration, with the lowest utility and caustic consumption.

- advanced, proven technology – only 3rd gen validated TTD

- variable process – time, temp, caustic, wet or dry discharge

- fully automated – press START and walk away

- minimal material handling – no bone basket

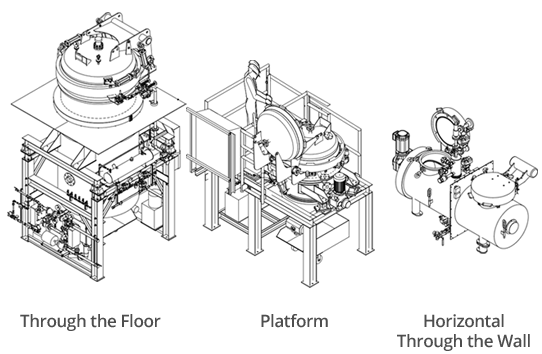

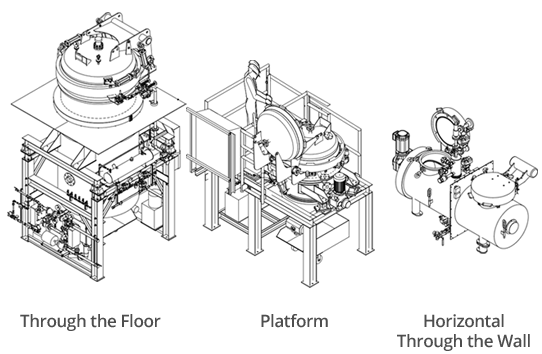

- flexible design – configurable to meet client needs

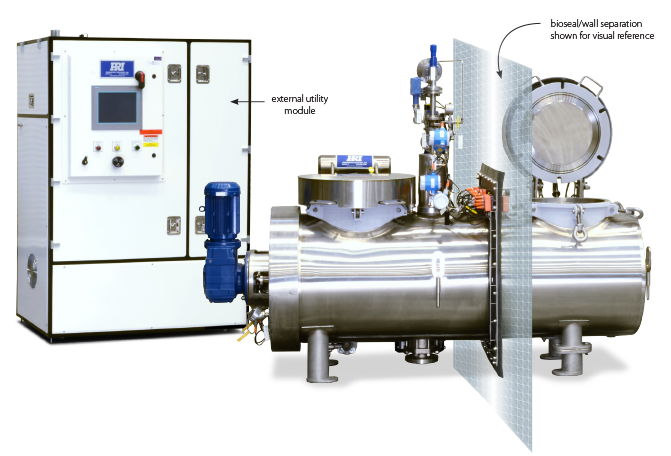

- designed for biocontainment – BSL-3, BSL-4 capable

Advanced Technology & Design

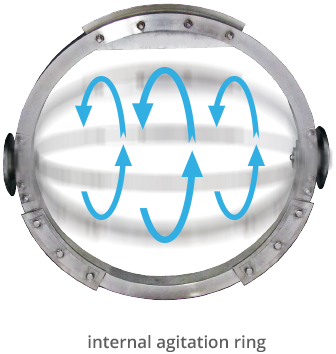

Internal agitation – no basket, no remnants, low labor.

The Thermal Tissue Digester’s (TTD) biokill process ensures proper breakdown of tissue and sterilization of the contents of the vessel. By combining time, temperature, agitation, and caustic, the TTD offers the most efficient, safe on-site solution to carcass disposal and sterilization.

- proprietary agitator designed for maximum mixture

- variable speed drive processes load into a homogenous slurry

- durable double-mechanical seals w/pressure monitored barrier fluid

- process fluids contained in ASME pressure vessel

- no pressurized contaminated piping system

- Prion inactivation based on published guidelines

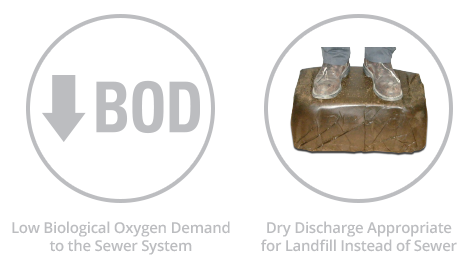

Wet or Dry Discharge

Variable discharge capabilities keep you compliant with changing regulations.

Because the Thermal Tissue Digester’s (TTD) use dramatically less caustic or water in the breakdown and sterilization process, it offers a dry discharge option in addition to the standard wet discharge. For many applications, this option is favorable, due to sewer regulations which are concerned about high Biological Oxygen Demand (BOD) in the sanitation system. The dry discharge “cake” can be sent to landfill, or, in some cases, used in agriculture applications.

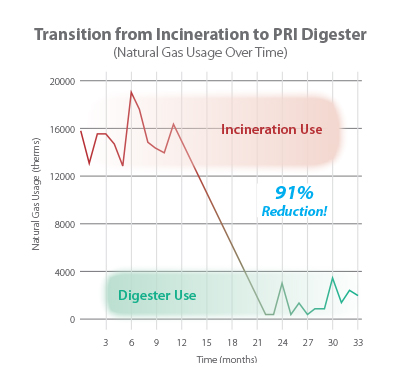

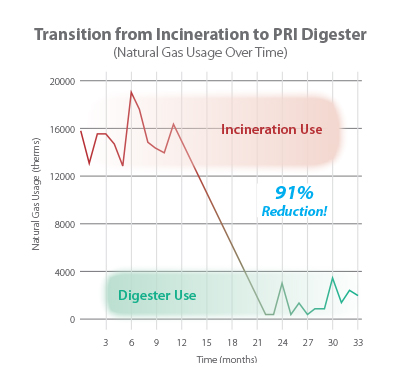

Cost-Effective Alternative to Incineration

Tissue Digester systems have proven to be a dramatically more cost-effective, environmentally friendly solution for destruction and sterilization of pathological waste.

Clients have reported over 90% reduction in natural gas usage over incineration while increasing throughput by as much as 23%.

PRI Tissue Digesters offer a safe, energy efficient, on-site solution which prevents the liability of transporting hazardous biowaste material. PRI’s TTD with wet discharge offers the lowest operating cost available for disposal and sterilization of hazardous waste material.

Biological Validation By Design

The Thermal Tissue Digester™ includes design features to allow routine validation of the system. We understand the importance of a properly functioning biowaste treatment system, and that our users require routine validation. It is for these reasons that all of our biowaste treatment systems have built-in validation design features to allow staff to ensure the process is effective and leads to consistent results, without making the process cumbersome or inconvenient for you.

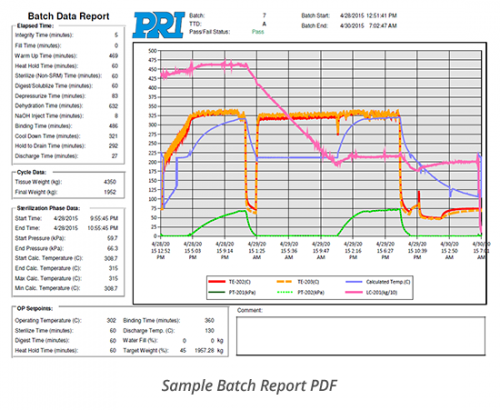

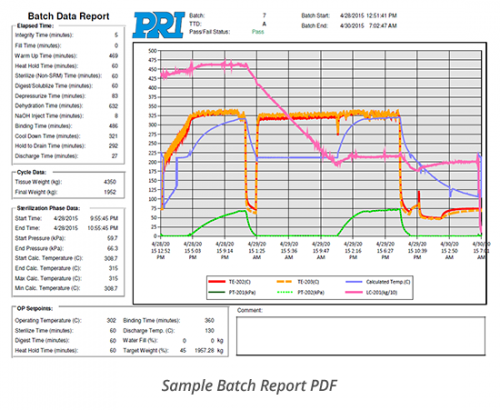

Batch Reporting Software

Data Logging, Process Assurance

PRI’s batch report software continuously monitors the system and generates a “proof of process”, assuring employees, officials, and the public of a safe environment. The software collects the performance data for each batch and generates a report representing the Time, Temperature, and Pressure of the operation, proving the system performed to the set points during the testing phase. This validates that complete and proper treatment has been achieved. Other features and benefits include:

- Proof of process for public assurance

- Documented evidence for each batch

- Excellent troubleshooting tool

- Pass/fail result for each batch

- HMI display, printout, and PDF, historical data archive

Safe Handling & Loading Accessories

Designed to simplify the loading of material into a Thermal Tissue Digester (TTD), PRI offers two optional custom-designed tipping solutions. Electric or manually operated tipping units hook directly to an existing hoist or lift mechanism, allowing the operator to guide material safely toward the digester.

Electric Tote-Tipper: hooks directly to an existing hoist or lift mechanism. Push-button tilt activation switch is built into the handle, allowing hydraulic cylinders to easily, safely tip the cart, delivering contents to the digester.

Manual Barrel-Tipper: hooks directly to an existing hoist or lift mechanism. Barrel can be wheeled toward the tipping device, and secured with the chain. The lifting mechanism secures the barrel while the contents are transferred manually into the digester.

Sizes & Specifications

| Model | Configuration | Nominal Load |

| 12 TTD-150 H | Horizontal | 75 kg (150 lbs) |

| 18 TTD-300 H | Horizontal | 150 kg (300 lbs) |

| 24 TTD-500 H or V | Horizontal or Vertical | 225 kg (500 lbs) |

| 36 TTD-600 | Vertical | 300 kg (625 lbs) |

| 48 TTD-1500 | Vertical | 600 kg (1500 lbs) |

| 60 TTD-3000 | Vertical | 1200 kg (3000 lbs) |

| 72 TTD-5000 | Vertical | 2300 kg (5000 lbs) |

| 84 TTD-8000 | Vertical | 3600 kg (8000 lbs) |

| 96 TTD-1000 | Vertical | 5000 kg (11000 lbs) |