BSLXstream™ Ecodas by PRI™ Containment Regulated Waste Shred & Steam Sterilizers

BSLXstream™ is designed for to treat many different types of high containment solid infectious waste. The most advanced of the three systems, the BSLXstream™ offers additional biosafety and biosecurity features.

Safely & Effectively Treat Solid Waste in High Containment

Shred & Steam Sterilize Bedding, Medical Waste, Plastics, Sharps & More

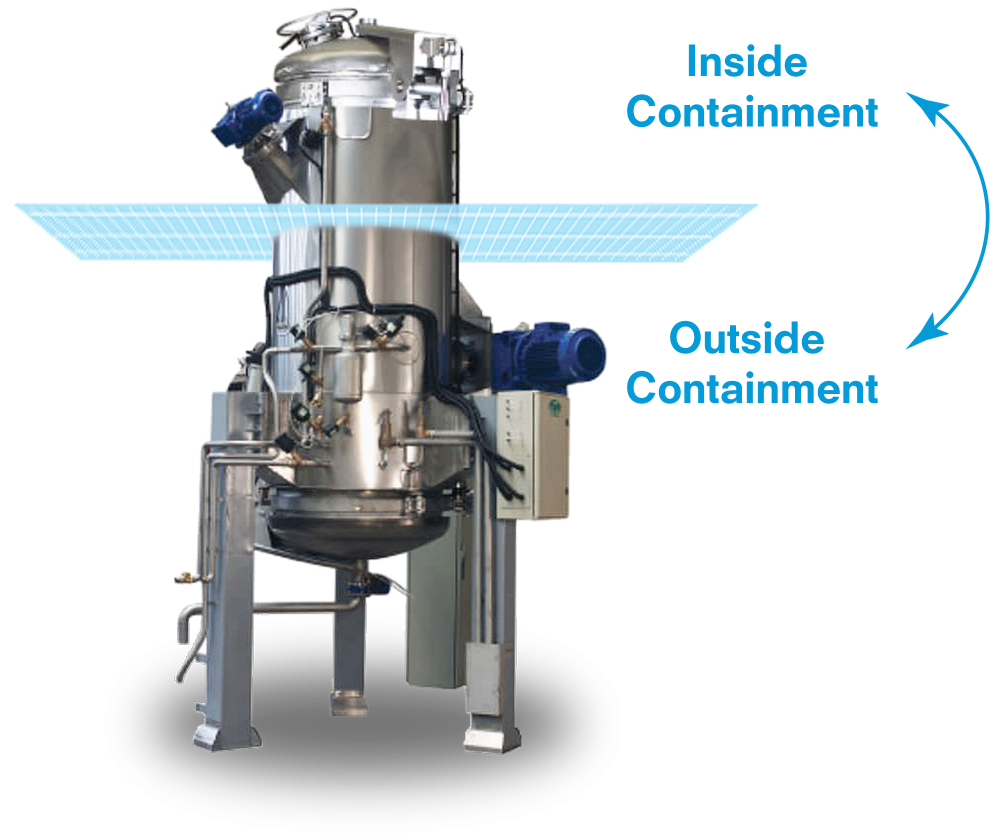

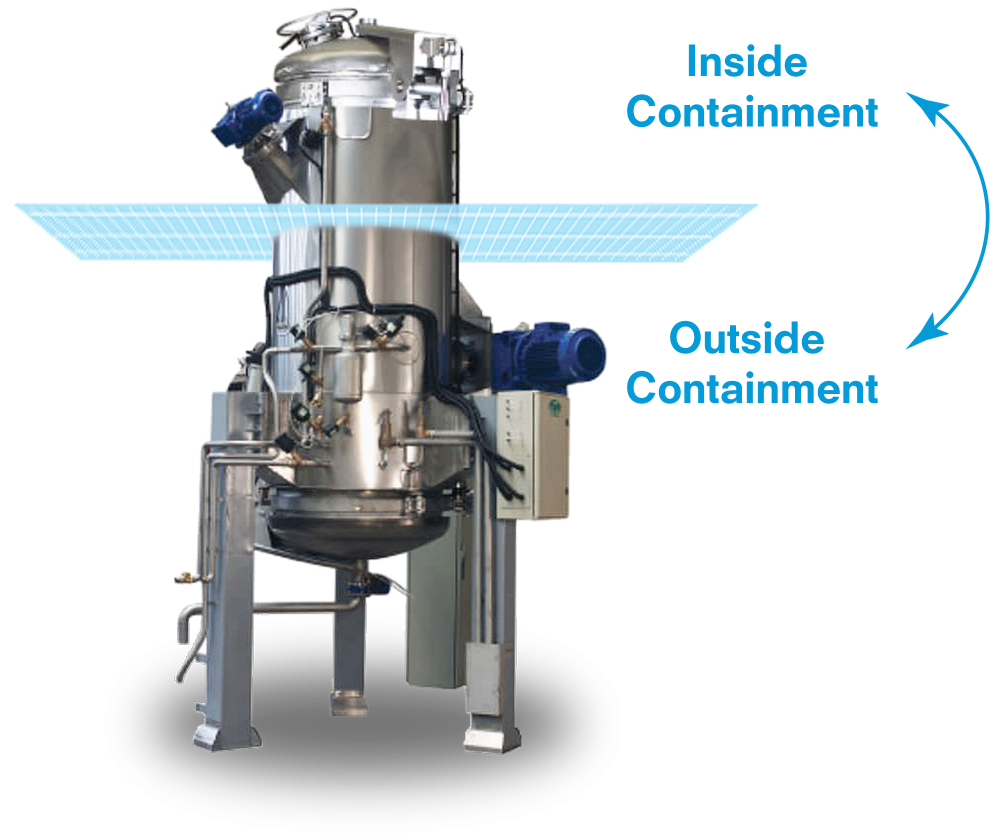

The BSLXstream™ takes the proven hybrid shred and steam sterilization system and adds high-containment biosafety features to enable users to treat solid infectious waste such as animal bedding, sharps, plastics and more, without leaving the containment space.

- designed with pressure-tight bioseal

- fully sealed system, with status monitoring for all vessel penetrations

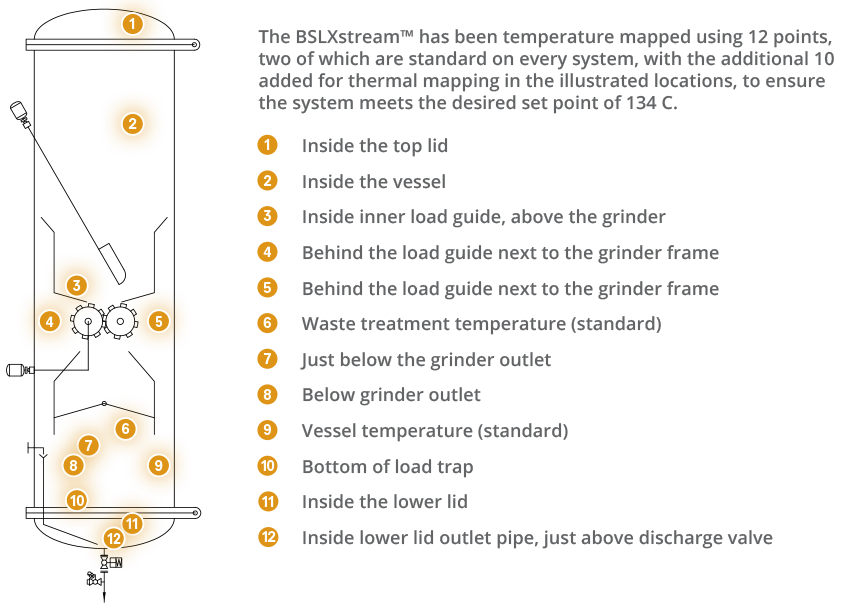

- temperature-mapped to ensure desired setpoint is achieved

- sterile vent filtration systems if required

- discharge liquids to effluent decontamination system to meet BSL-3 and 4 treatment requirements

Effective, Proven Shred & Steam Sterilization Process

The BSLXstream™ process shreds all infectious solid waste material once the vessel lid is closed, prior to the start of the steam treatment cycle, to ensure the efficacy of the steam sterilization throughout the load. The system uses direct heated steam and pressure to completely sterilize infectious waste, surpassing traditional autoclaving by rendering the waste unrecognizable due to the integrated shredder system.

Temperature, pressure and time are continuously monitored and maintained through the integrated control system. Achieves microbial inactivation greater than 106.

Designed for High Containment

Safely treats high containment solid infectious waste.

PRI’s experience in high containment biosafety engineering has been applied to this system, with attention to detail:

- Flush mount discharge to ensure clean thorough drain

- Multiple sealing systems and status monitoring of all vessel penetrations

- Pressurized bioseal-ready

- Pressure relief systems with available vent filtration

- Fully seal welded insulated vessel above the bioseal

- Specially-designed steam injection system to ensure all parts of the vessel are at sterilization temperature

- Utility verification prior to beginning of cycle

- Separate discharge of liquid waste and flash steam to EDS

Can Integrate with Effluent Decontamination System

To Meet Facility or Regulatory Requirements

During the treatment cycle, steam is injected directly into the system, and temperature and pressure reaches All liquids from the BSLXstream™ can be piped to an Effluent Decontamination System (EDS) if your facility or local regulations require.